Understanding Fire Rated Chemical Storage Cabinets

Fire rated chemical storage cabinets are essential safety equipment in any facility that handles hazardous chemicals. They are designed to protect valuable assets and personnel from the dangers of fire and explosions by containing hazardous materials and preventing their spread in the event of a fire. These cabinets are specifically designed to withstand high temperatures for a specified duration, ensuring that the contents remain secure and do not contribute to the spread of fire.

Types of Fire Rated Chemical Storage Cabinets

The type of fire rated chemical storage cabinet you choose will depend on the specific hazards you need to contain and the level of protection required. Different types of cabinets are available, each with its own construction materials and features.

- Metal cabinets: These are the most common type of fire rated chemical storage cabinets. They are typically made of steel or stainless steel and offer excellent durability and resistance to corrosion. Metal cabinets are often coated with a fire-resistant paint to further enhance their protection.

- Plastic cabinets: Plastic cabinets are a lightweight and cost-effective option. They are typically made of high-density polyethylene (HDPE) or polypropylene (PP) and are resistant to a wide range of chemicals. However, plastic cabinets may not offer the same level of fire protection as metal cabinets.

- Combination cabinets: These cabinets combine the features of both metal and plastic cabinets. They may have a metal frame with plastic doors or a plastic body with a metal door. This combination provides a balance of durability, corrosion resistance, and cost-effectiveness.

Safety Standards and Regulations

Fire rated chemical storage cabinets are subject to strict safety standards and regulations to ensure they meet the required levels of protection. These standards are typically established by organizations such as the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA).

- NFPA 45: This standard Artikels the requirements for the storage and handling of hazardous materials. It specifies the minimum fire resistance rating for chemical storage cabinets based on the type of chemicals being stored.

- OSHA 29 CFR 1910.106: This regulation covers the handling of hazardous materials in the workplace. It requires employers to provide safe storage facilities for hazardous chemicals, including fire rated cabinets.

Key Features and Benefits of Fire Rated Chemical Storage Cabinets

| Feature | Benefit |

|---|---|

| Fire Resistance Rating | The fire resistance rating of a cabinet indicates how long it can withstand a fire without compromising the integrity of the cabinet and allowing the contents to ignite. This rating is typically measured in hours. |

| Construction Materials | The construction materials used in the cabinet should be resistant to the specific chemicals being stored and should provide adequate fire protection. Metal cabinets are generally considered to be more durable and fire-resistant than plastic cabinets. |

| Ventilation | Proper ventilation is essential to prevent the buildup of flammable vapors inside the cabinet. Cabinets should have vents that allow for air circulation. |

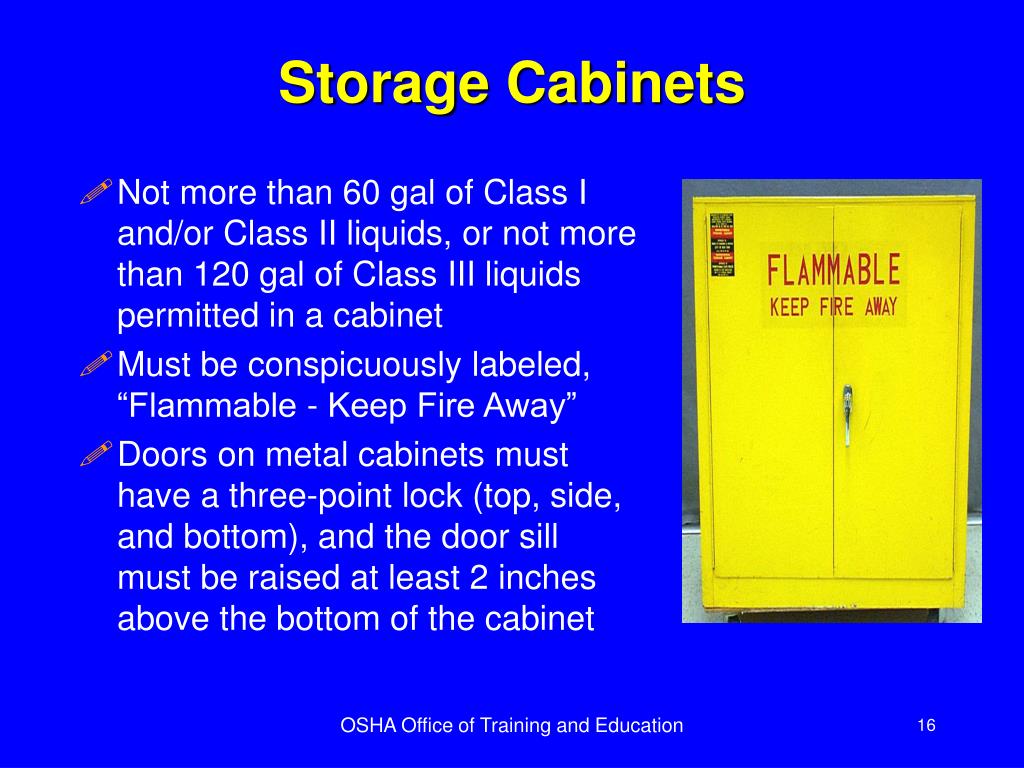

| Locking Mechanism | A secure locking mechanism is crucial to prevent unauthorized access to hazardous chemicals. Cabinets should have a robust lock that can withstand attempts to break in. |

| Labeling and Identification | Cabinets should be clearly labeled to indicate the type of chemicals stored inside. This helps to ensure that the appropriate safety precautions are taken when handling the chemicals. |

| Spill Containment | Some cabinets include a spill containment system to prevent the spread of hazardous materials in the event of a spill. This system may consist of a tray or a liner that collects any spills. |

Factors to Consider When Choosing a Fire Rated Chemical Storage Cabinet

Choosing the right fire rated chemical storage cabinet is crucial for ensuring the safety of your workplace and the environment. Several factors need careful consideration to select a cabinet that meets your specific needs and complies with relevant regulations.

Compatibility with Stored Chemicals

The most important factor when choosing a fire rated chemical storage cabinet is compatibility with the chemicals being stored. Different materials used in cabinet construction have varying levels of resistance to specific chemicals. For example, some cabinets are designed for storing acids, while others are suitable for storing flammable liquids. Choosing a cabinet incompatible with the stored chemicals can lead to corrosion, leaks, and even explosions.

- Consult the manufacturer’s specifications to ensure the cabinet is compatible with the specific chemicals you intend to store.

- Look for cabinets made of materials resistant to the chemicals being stored, such as stainless steel, polypropylene, or polyethylene.

- Consider the chemical’s properties, including its corrosiveness, flammability, and reactivity, when selecting a cabinet.

Cabinet Size, Capacity, and Accessibility

The size and capacity of the cabinet are essential considerations. The cabinet should be large enough to accommodate all the chemicals you need to store, but not so large that it becomes difficult to access or manage. Accessibility is crucial for safe and efficient chemical handling.

- Consider the volume of chemicals you need to store and the size of the containers.

- Choose a cabinet with adjustable shelves or drawers to maximize storage space and accommodate different container sizes.

- Ensure the cabinet has easy-to-open doors and a clear view of the stored chemicals.

- Choose a cabinet with a convenient location for easy access and safe handling.

Features and Specifications

Fire rated chemical storage cabinets come with various features and specifications that impact their performance and safety.

| Feature | Description | Considerations |

|---|---|---|

| Fire Rating | Indicates the cabinet’s ability to withstand fire for a specific duration. | Choose a cabinet with a fire rating that meets the requirements of your specific application and local regulations. |

| Ventilation | Allows for proper air circulation to prevent the buildup of flammable vapors. | Ensure the cabinet has adequate ventilation to prevent the accumulation of hazardous gases. |

| Spill Containment | Prevents spills from spreading and contaminating the surrounding environment. | Choose a cabinet with spill containment features, such as a sump or a drip tray. |

| Safety Features | Includes features such as lockable doors, warning labels, and emergency eye wash stations. | Select a cabinet with appropriate safety features to ensure the safety of personnel. |

Installation and Maintenance of Fire Rated Chemical Storage Cabinets

Proper installation and regular maintenance are crucial for ensuring the effectiveness and longevity of fire-rated chemical storage cabinets. These cabinets are designed to protect valuable assets and personnel from fire hazards associated with flammable and corrosive chemicals.

Best Practices for Installation

- Location: Choose a well-ventilated area away from heat sources, direct sunlight, and high traffic zones. Ideally, the location should be easily accessible for emergency personnel.

- Foundation: Ensure a stable and level foundation. Consider using a concrete pad or a sturdy platform to support the weight of the cabinet and its contents.

- Clearance: Maintain sufficient clearance around the cabinet to allow for ventilation and easy access for maintenance and emergency response. Ensure at least 12 inches of clearance from walls and other obstructions.

- Electrical Connections: If the cabinet includes electrical components, such as ventilation fans or lighting, ensure proper electrical wiring and grounding. Consult with a qualified electrician to ensure compliance with local codes and regulations.

- Fire Suppression Systems: If the cabinet is equipped with a fire suppression system, ensure it is properly installed and tested regularly. Consult with a fire protection specialist for installation and maintenance guidelines.

Safe Handling and Storage of Chemicals, Fire rated chemical storage cabinets

- Compatibility: Ensure that chemicals stored together are compatible. Refer to the Safety Data Sheet (SDS) for each chemical to determine compatibility guidelines.

- Labeling: Clearly label all containers with the chemical name, hazard warnings, and relevant safety information. Use durable labels that are resistant to chemicals and heat.

- Storage Practices: Store chemicals in their original containers, with lids securely closed. Avoid overfilling containers. Store heavy items on lower shelves to prevent instability.

- Ventilation: Ensure adequate ventilation to prevent the buildup of harmful fumes. If necessary, install a ventilation system with a fan to exhaust fumes outside the building.

- Emergency Procedures: Develop and implement emergency procedures for handling chemical spills and leaks. Ensure that all employees are trained on these procedures.

Importance of Regular Maintenance and Inspection

Regular maintenance and inspection are essential to ensure the continued effectiveness and safety of fire-rated chemical storage cabinets. This involves a systematic approach to identify and address potential problems before they become major safety hazards.

Routine Maintenance Procedures

- Cleaning: Regularly clean the interior and exterior of the cabinet to remove dust, debris, and chemical spills. Use a mild detergent and water for cleaning. Avoid using abrasive cleaners that could damage the cabinet’s finish.

- Inspection: Conduct a thorough inspection of the cabinet at least annually, or more frequently if needed. Check for signs of damage, such as cracks, dents, or corrosion. Inspect the door seals, hinges, and latches for proper function.

- Fire Suppression System: If the cabinet is equipped with a fire suppression system, ensure it is properly maintained and tested regularly. Follow the manufacturer’s instructions for testing and maintenance procedures.

- Ventilation System: Inspect the ventilation system for proper operation. Check the fan, filters, and exhaust duct for any blockages or damage.

- Electrical Components: If the cabinet includes electrical components, ensure they are properly wired and grounded. Inspect the wiring for signs of damage or wear. Test the electrical components for proper function.

Fire rated chemical storage cabinets? Yeah, those are pretty important for, you know, not burning down your entire lab. But let’s be honest, who really wants to stare at a boring metal box all day? Maybe you need a little more… visual interest?

Check out these awesome big screen tv cabinets , they’re like a whole different level of stylish. Anyway, back to the chemicals… just make sure those cabinets are properly vented, alright? We don’t want a repeat of that “exploding beaker” incident, right?

Fire rated chemical storage cabinets are like those old, sturdy safes your grandpa used to keep his war medals in. They’re built to withstand the heat and protect valuable stuff. But unlike those safes, you won’t find any vintage Motorola TV cabinets inside.

Those beauties are better suited for a living room, not a lab. And speaking of living rooms, you can find some really cool vintage Motorola TV cabinets on this website if you’re into that retro vibe. Anyway, back to fire rated cabinets – they’re essential for keeping your chemicals safe and your lab from turning into a fiery inferno.